Cover

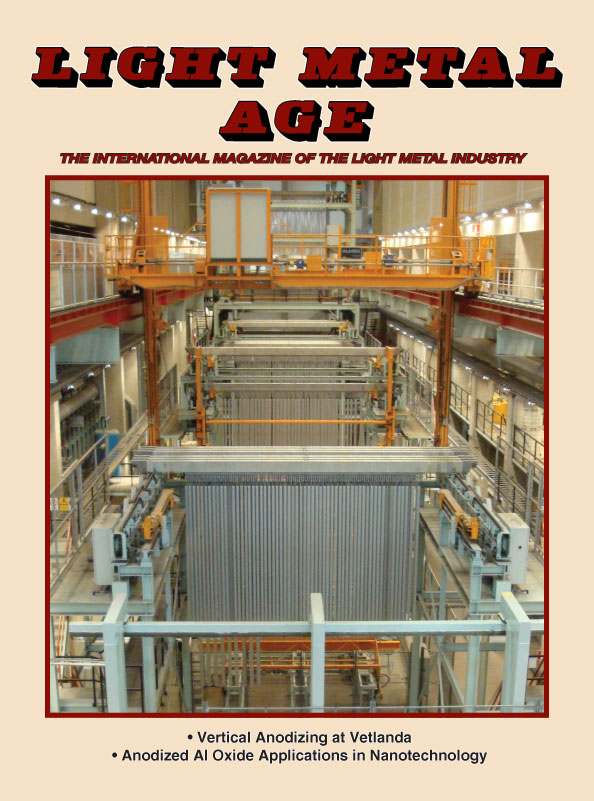

A recent tour of the vertical anodizing line at Sapa Profiles in Vetlanda, Sweden showcases the advantages of vertical versus horizontal anodizing, which include: less floor space required, 25% less drag out of chemicals, faster clamping system, and based on a vertical line with tanks 5-6 m or more, production capacity is 5-10 times that of a horizontal line. Photo is taken from the end of the line. Load has been anodized and sealed and is ready to be packed. (Photographer: Rose Fellom-Morris.)

Articles

Improving Efficiency with Vertical Anodizing at Sapa Profiles in Vetlanda

By Anne Deacon Juhl

Page 6

Purchase Article

Anodized Aluminum Oxide Applications as Nanomembranes and Nanotemplates in Electronic Devices, Energy Conversion, Sensors, and Medicine

By Joseph C. Benedyk

Page 12

Purchase Article

The Goal of Optimizing Aluminum Extrusion Operations, Part I: Extrusion Certification

By Craig Werner

Page 22

Purchase Article

CAST: Integrating Australian Research and Industry Benefiting Light Metal Technologies

By Andrea Svendsen

Page 30

Purchase Article

Aluminum Illuminates Rural Villages in India

Page 36

Purchase Article