Cover

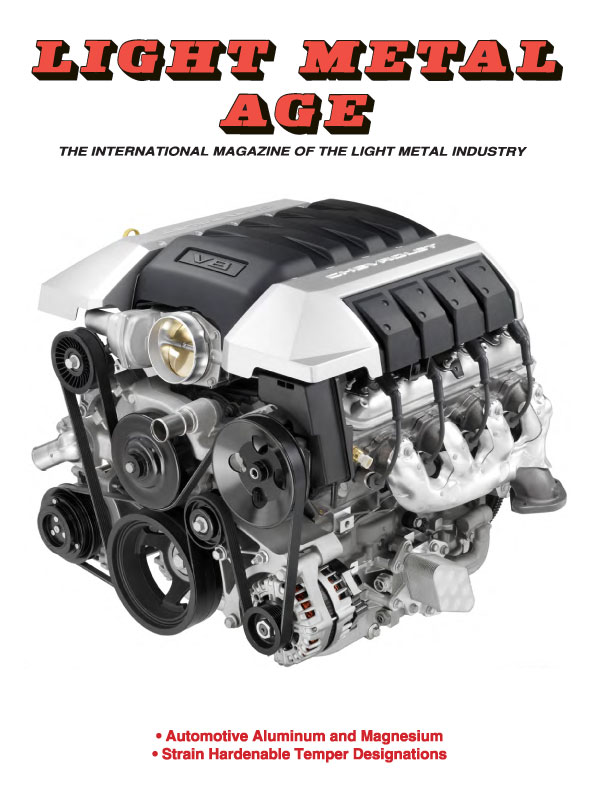

Photo shows the V8 aluminum engine (weighing 204 lbs) for the 2010 Chevrolet Camaro (printed with permission ©GM Comp.). Engines continue to be the highest volume component for aluminum in automotive applications. The Camaro contains 10% aluminum by vehicle curb weight, including engine blocks and heads, pistons, hood, wheels, transmission housing, differential housings, and brake calipers. Both aluminum and magnesium have shown steady growth in automotive since the 1970s. A number of forming technologies as well as improvements in material properties and cost will increase their greater use inthe future.

Articles

Automotive Aluminum and Magnesium: Innovation and Opportunities

By Paul Krajewski, Anil Sachdev, Alan Luo, John Carsley, and Jim Schroth

Page 6

Offline Programming Enables Robotized 3D-Curved Profile Extrusion

By Dr. J. Bickendorf and Dr. S. Gasper

Page 14

ICEB 2009 Dortmund: International Conference on Extrusion and 3rd Extrusion Benchmark

By N. Ben Khalifa, A.E. Tekkaya, L. Donati, and L. Tomesani

Page 20

Interview with Tim Stubbs, president, Sapa Profiles North America: With Indalex, Sapa Now Has Unmatched Range of Capabilities

Page 24

International Temper Designation Systems for Wrought Aluminum Alloys: Part I – Strain Hardenable (H Temper) Aluminum Alloys

By Joseph C. Benedyk

Page 26

UC Rusal Responds Following Catastrophic Accident at Sayano-Shushenskaya Power Plant

By Alton Tabereaux

Page 32

Magnesium Recycling: State-of-the-Art Developments, Part II

By Daniel Fechner, Norbert Hort, Carsten Blawert, Wolfgang Dietzel, and Karl Ulrich Kainer

Page 34

Hydraulic Upgrade on 2400 UST Press at Kawneer’s Bloomsburg Facility

By Joseph C. Benedyk

Page 38

TMS’09 Photo Layout

Page 40

Global Aluminum Content in Autos

Page 44