The ET Foundation, the educational and research organization devoted to promoting and advancing aluminum extrusion processes and technologies, and Bonnell Aluminum are inviting entries for the 2016 International Aluminum Extrusion Design Competition. The 2016 competition is divided into two classes: Professional and Student. Bonnell Aluminum is the sole sponsor for the cash awards, totaling $20,000, including a Grand Prize of $3,500 awarded to the best design across all categories and classes. The 2016 Design Competition will include a new student design category, the Bonnell Aluminum LED Lighting Design Challenge, which encourages students to think about aluminum extrusions as a holistic solution to a design problem.

Professional designers, engineers, and manufacturers along with students studying design and engineering at universities, colleges, technical schools and high schools around the world are invited to participate. The ET Foundation will accept entries for the 2016 International Aluminum Extrusion Design Competition through March 7, 2016. Entry in the competition is free and judging will take place following the entry deadline.

Winning designs from this and previous competitions will be on display at the Eleventh International Aluminum Extrusion Technology Seminar and Exposition – ET ’16, scheduled for May 2-6, 2016 in Chicago, Illinois. The ET Seminar is the longest running and most respected technical conference in the industry devoted to worldwide advancements in aluminum extrusion technology, equipment, processes, applications, and more.

Student Class

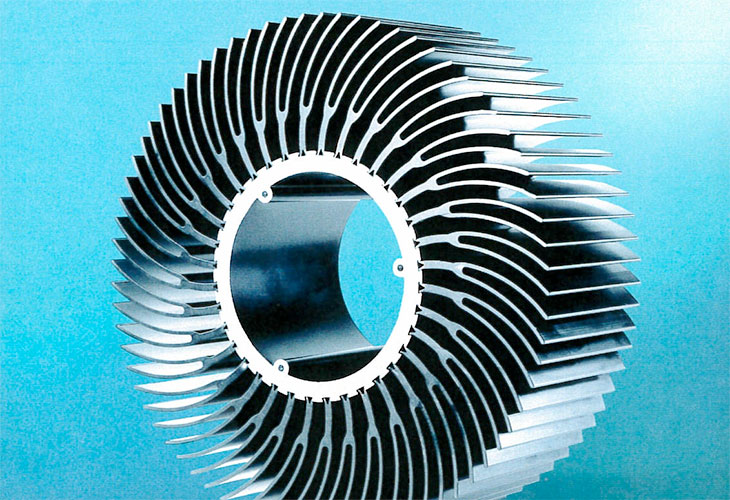

Student scholarships will be presented as cash awards to the top student designs, including $3,000 for First Place, $2,000 for Second Place, and $1,000 for Third Place. Students also may compete for the Bonnell Aluminum LED Lighting Design Challenge Scholarship Award of $2,500. The LED Lighting Design Challenge tasks students with designing an LED lighting application that uses aluminum extrusions, while addressing some of the material’s excellent advantages, including aluminum’s superior heat dissipation properties, natural reflectivity, light weight, ease of fabrication, and the designer’s ability to create complex integral shapes that are joinable with various methods and materials, to name just a few. Designers must also take into consideration the limitations of the aluminum extrusion process.

“Many of the student designs in previous competitions were clever ideas but they lacked practicality,” said Design Competition judge David Asher, process optimization manager for Bonnell Aluminum. “With this new category we want to encourage students (and their instructors) to better understand the aluminum extrusion process and all of its advantages. Don’t design a part that is overly wide and will need to be manufactured on a 24 inch press. The reality is that there are very few presses that can handle that profile size, and the cost for extruding that part is simply not practical. Addressing issues such as this will impact the judging process. The winning design will really come down to whether or not the student has a good understanding of the aluminum extrusion process.”

Students currently enrolled in a college, university, or technical school, including graduate students, are eligible to enter the Student Design Competition. Entries from high school students also will be accepted.

Professional Class

Entries received in the Professional Class will be divided into four categories: Structural/Architectural, Transportation, Engineered Products, and Alternative Energy. First-place cash prizes in the amount of $2,000 will be awarded to the best design in each category. Individual designers and companies are eligible to enter the Professional Design Competition. Aluminum extruders and their customers are encouraged to team up to enter their design in the Competition. Team and multiple submissions will be accepted for both the student and professional classes.